Breaking the Barrier: How 3D Printing can be Accessible

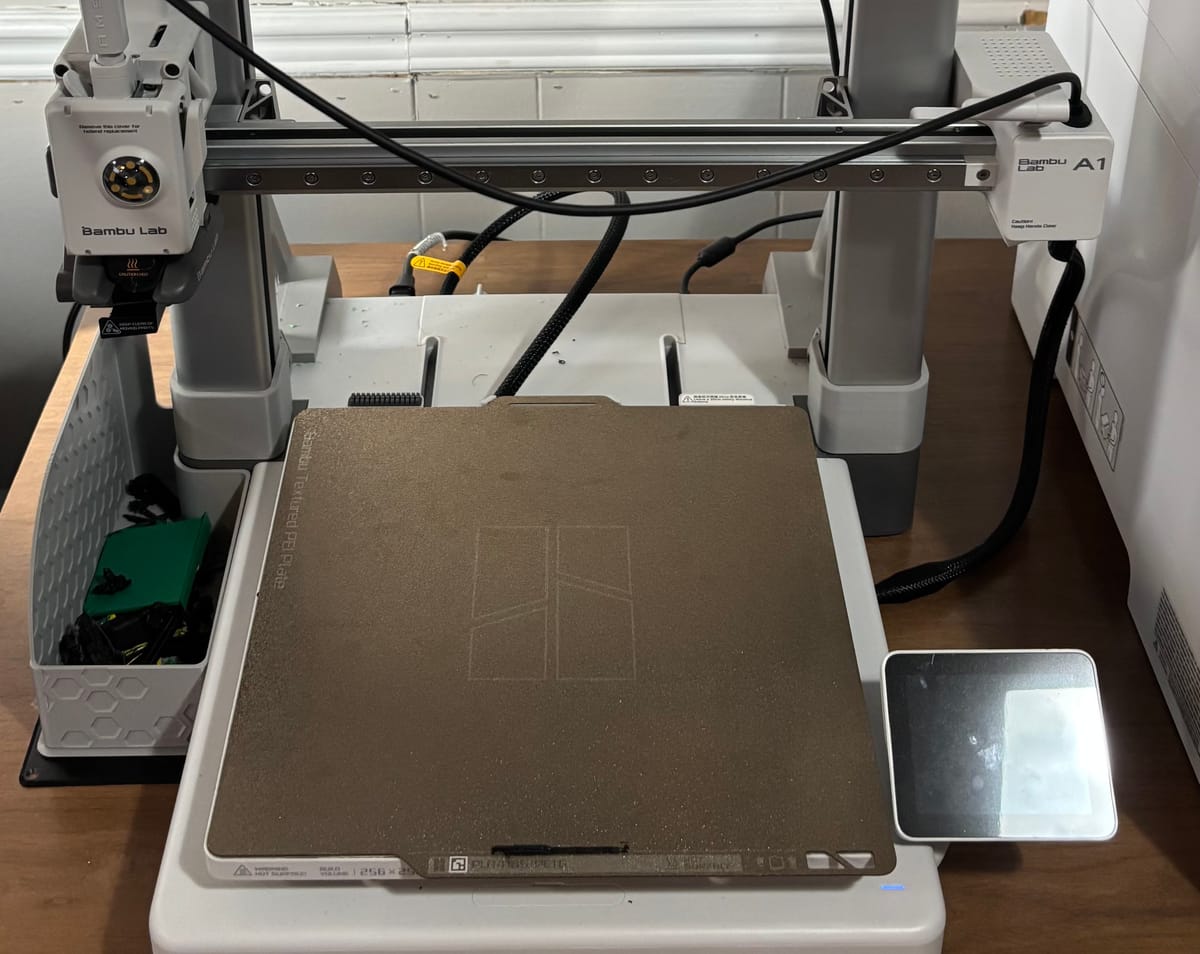

Once a complicated hobby for experts, 3D printing is now within reach of anyone curious enough to try it. Bambu Lab’s A1 and AMS Lite show how far the technology has come.

3D printing used to feel like a science experiment. Early machines were expensive, hard to use, and often unreliable. Getting a good print sometimes meant days of tweaking settings and hoping for the best. This made 3D printing popular only with serious hobbyists who were willing to spend the time and effort.

But things have changed. Over the last few years, 3D printing has become more affordable and easier to use. Today, machines like the A1 from Bambu Lab make it possible for almost anyone to try 3D printing. You no longer need to be an expert or have hours of free time to get started.

This article explores how we got here. First, we’ll look at how 3D printing evolved and the challenges that held it back. Then, we’ll take a closer look at the Bambu Lab A1 and the AMS Lite, which bring reliability and ease of use to the table. Finally, we’ll explore how users are turning their prints into everyday tools, and even small businesses.

Learning about 3D Printers

Most consumer 3D printers fall into one of two types: filament and resin.

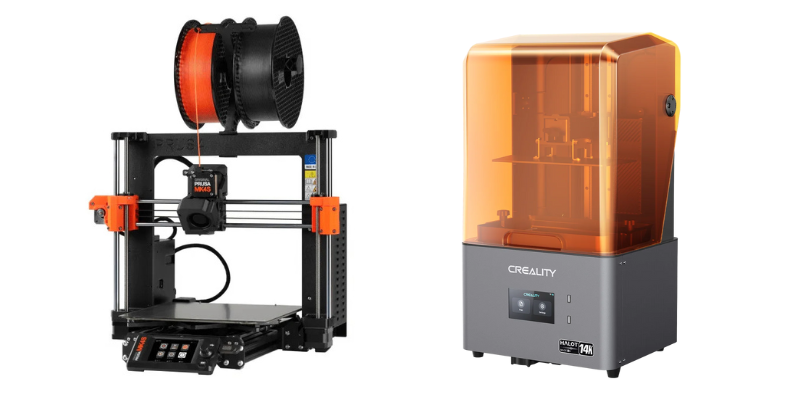

Filament printers work by melting plastic thread, called filament, and laying it down one layer at a time to build an object. These printers are usually better for making larger, functional items like tool organizers, phone stands, or toys. They are safer to use, cleaner, and easier to maintain.

Resin printers use special liquid resin that hardens when hit with ultraviolet (UV) light. These printers can produce incredibly detailed models, which is why many people use them for miniatures or jewelry. But they also require more work and care. The resin is messy, sometimes toxic, and needs to be cleaned off after printing.

Because of this, most people who are new to 3D printing start with filament printers. But even among those, getting started wasn’t always easy.

A few years ago, people who wanted to try 3D printing had a tough choice. They could buy a high-end printer like a Prusa, which was well made but expensive. Or they could go with a more affordable printer like a Creality, which cost less but often came with challenges. These machines worked, but they needed frequent repairs, tricky calibrations, and manual upgrades.

If you weren’t already familiar with tools or software, it was easy to get discouraged. That barrier, more than price, kept 3D printing out of reach for beginners.

The Bambu Lab Experience

Bambu Lab approached the challenges of 3D printing from a user-first perspective. Instead of designing a machine that demanded expertise, they created one that invited curiosity. The A1 is compact, quiet, and fast. Most importantly, it works with minimal fuss. It arrives mostly pre-assembled, includes automatic bed leveling, and offers guided calibration that removes much of the guesswork that used to define filament printing. The touchscreen interface is straightforward, and for those who prefer app-based control, Bambu’s companion software integrates cloud printing, firmware updates, and filament tracking.

The full setup experience feels more like unboxing a finished consumer product than assembling a machine. Bambu’s packaging is clean and well-labeled. Tools are included. Instructions are printed and available online. Sample filament and preloaded test files mean most users can go from box to print in under an hour.

Part of what makes the A1 especially accessible is its compatibility with the AMS Lite, Bambu’s Automatic Material System. This external feeder can hold up to four spools of filament and switch between them during a print. For beginners, this means seamless multi-color results without stopping the machine. For more advanced users, it enables backup rolls and simplified filament management, helping reduce print failures caused by tangles or roll depletion.

Much of the printing experience, however, comes down to the material itself. Most new users start with PLA (Polylactic Acid), a biodegradable plastic made from renewable resources like corn starch. PLA prints at low temperatures, doesn’t require a heated chamber, and is easy to work with on open-frame printers like the A1. It adheres well to the bed, rarely warps, and is available in a wide range of colors and finishes, including silk, matte, translucent, and specialty effects.

As users gain confidence, many move on to PETG (Polyethylene Terephthalate Glycol). It’s stronger than PLA, more resistant to UV and moisture, and better suited for prints that will be used outdoors or handled frequently. PETG prints at slightly higher temperatures and benefits from good part cooling, but the A1 handles it well with minimal adjustment. For most hobby and functional prints, PLA and PETG cover a wide range of use cases.

More advanced materials are available. ABS, for example, is known for its strength and heat resistance, and is used in products like LEGO bricks. However, it is difficult to print reliably without an enclosed, temperature-controlled environment. It also produces fumes that require ventilation. The A1 is not designed for ABS, but printers in Bambu’s higher-end X1 series or enclosed machines from other manufacturers may be better suited for those needs.

For the majority of users, though, PLA and PETG are more than sufficient. They offer a wide mix of durability, appearance, and ease of use. On the A1, both materials are simple to load, monitor, and reuse, especially when paired with the AMS Lite.

Cloud Concerns

While the A1 is easy to use, not everything about Bambu Lab’s ecosystem has been well received. In early 2024, the company released a firmware update that made the printers more dependent on cloud services. Features that used to work offline, like printing from an SD card, now required an internet connection and access to Bambu’s servers.

The community reaction was immediate. Many users were frustrated that something as simple as starting a print could suddenly fail if the printer wasn’t online. Others raised concerns about privacy, data tracking, or what would happen if Bambu’s servers ever shut down.

These fears weren’t unreasonable. In other industries, cloud-tied products have become less useful, or completely useless, when a company changes its policies or shuts down its servers. For people who rely on their printers for work or education, that risk feels personal.

Bambu has since offered a limited offline mode, but the conversation isn’t over. The episode is a reminder that even well-designed hardware needs thoughtful software, and that convenience should never come at the cost of control.

From Print to Business

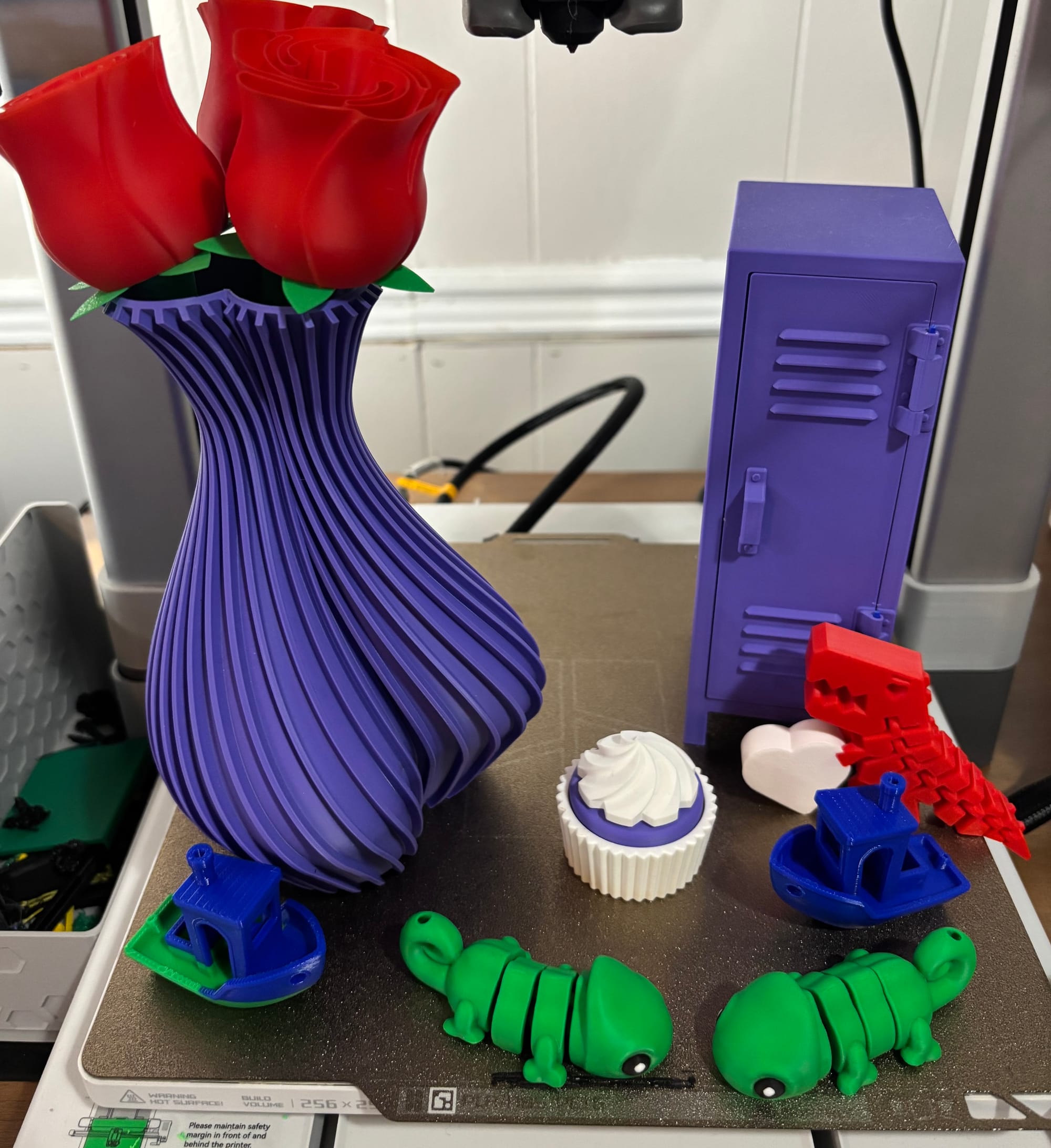

The traditional first print for any new 3D print owner is Benchy, a tugboat model used across the 3D printing community to evaluate performance. It challenges the printer with overhangs, fine details, and curved geometry. On the A1, the Benchy prints cleanly on the first attempt. Layers are aligned, edges are sharp, and the result is a satisfying success that would have taken hours of trial-and-error with older printers.

One early follow up might be a fidget toy, which tests how well a printer handles moving parts printed in one piece. Another might be a trading card box, carefully sized to hold sleeved cards. Decorative items like vases are popular too, especially with silk or transparent filament that shows off surface texture. A toolbox for organizing printer accessories is another good beginner project — useful and satisfying to complete.

Each of these prints helps users understand how filament behaves, what print settings matter, and how to improve results. But more importantly, they offer a glimpse of what’s possible.

That glimpse is what leads some people to turn 3D printing into more than a hobby. Small businesses built around 3D printing are growing fast, thanks to the low cost of entry and huge variety of printable products.

Some creators sell physical items on platforms like Etsy — nameplates, toys, game pieces, cosplay parts, or kitchen gadgets. Others design and sell digital files, earning income from STL downloads. A few even offer local print services to schools or businesses.

What all of these efforts share is a starting point: a reliable printer that’s easy to use. For many, those printers are made by Bambu Lab.

Anyone can Print

3D printing is still a deep and complex hobby, with plenty to learn. But it no longer has to start with frustration.

The Bambu Lab A1 and AMS Lite have set a new standard for entry-level printers. They’re fast, quiet, and easy to use — and they produce results that would have seemed out of reach just a few years ago. It’s now possible to go from unboxing to printing in under an hour, with no prior experience.

For anyone who once looked at 3D printing and thought, “That looks cool, but I’d never figure it out,” now might be the time to take a second look.